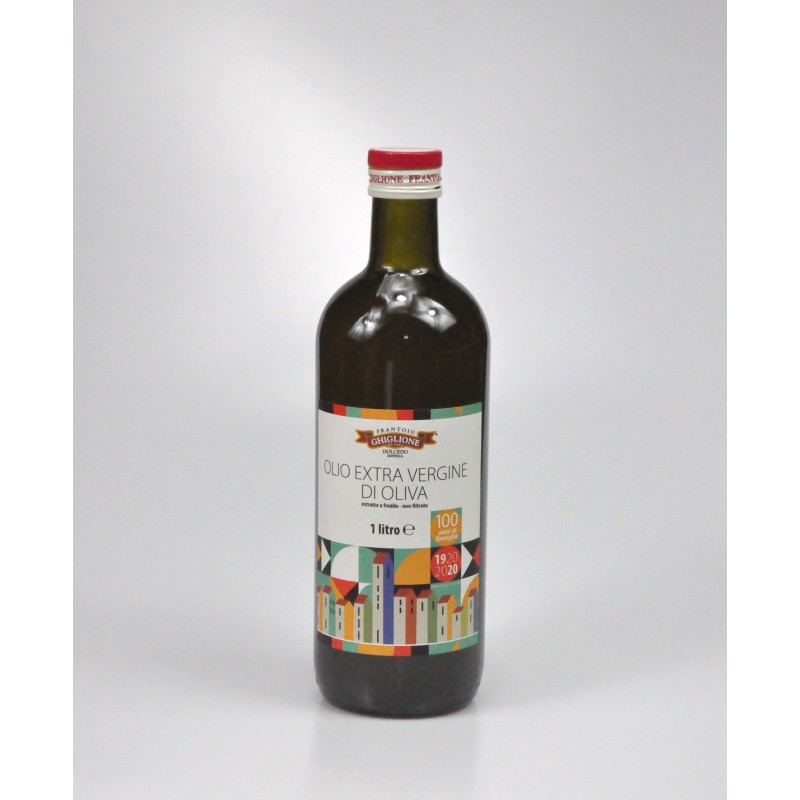

List of products by brand FRANTOIO GHIGLIONE

Frantoio Ghiglione

Frantoio Ghiglione, established in 1920, is situated in Dolcedo, a medieval village, 7 Km off the “Imperia Ovest” motorway exit.

Our valley is well known for its olive trees and the kind of olive grown here is called “Taggiasca” .

The extra virgin oil, derived from the special olive, is sweet, delicate and low in acidity.

Our family firm applies the experience gained by three generation and follows every step of the production: harvesting, pressing (for which we use a special method called “ a freddo” ) , packaging and home delivery.

Our ultimate aim is to supply a product of high quality.

You are welcome to come and visit us at any time of the year.

You will be able to find, besides our famous oil, typical produce of our valley.

We also produce a fine line of cosmetics including soaps, which have our olive oil as main ingredient.

Our large gift selection can also be taylor made for requirements.

::- production method -::

The olives, once collected and transported to the mill as soon as possible, undergo a series of procedures at the end of which we will get a golden thread of oil ready for our table. The transport of the drupes to the crushing areas must take place using well-ventilated baskets, which prevent the onset of mold and fermentation in the lower layers of the load. Before proceeding with the extraction phase, the olives are separated from the remaining foliage and impurities, at which point the olives are ready for pressing.

In this first phase the olives are crushed together with the stones, obtaining a still coarse pulp with wood fragments that perform a draining function, therefore, the paste thus obtained is subjected to the kneading, that is to a slow remixing in order to break the water emulsions. oil and obtain a separation between must oil and vegetation water. At this point we proceed to the actual extraction phase, which leads to the final separation of the three components of the pasta: pomace, vegetation water and oil. To be sure, there are different methods to obtain the finished product, which can be classified as discontinuous and continuous.

The most traditional discontinuous method is undoubtedly that for mechanical pressure; the pasta is placed on discs of vegetable fiber called fiscoli (today synthetic materials are used to guarantee hygiene) and everything is stacked under a press which, in the space of an hour, releases the oily liquid-oil must. The solid part that after adhering remains adherent to the fiscoli is the pomace; from this, with further procedures it will be possible to extract oil again, even if of a much lower quality.

Among the currently used continuous methods we mention centrifugation, which exploits the different specific weight of the individual components leading to the separation of the oil from the solid part and from the vegetation water.

The oil obtained at the end of these operations is cloudy and opalescent, a period of rest (decanting) is necessary during which the various foreign substances will settle on the bottom, after which the wine is decanted. Sometimes the oil can be further filtered, obtaining a product with a clear and bright color, without those vegetal particles that could accelerate the normal processes of rancidity.

At this point we have finally finished the various processes and the so-called "new oil" is ready to be distributed on the market and to enhance the flavors of our food.